No products

Fórum

FórumHow to work with decals

You can use decals similarly like the any other decals. However, they are specific in some respects, which exist due to the printing technology.

Decal application

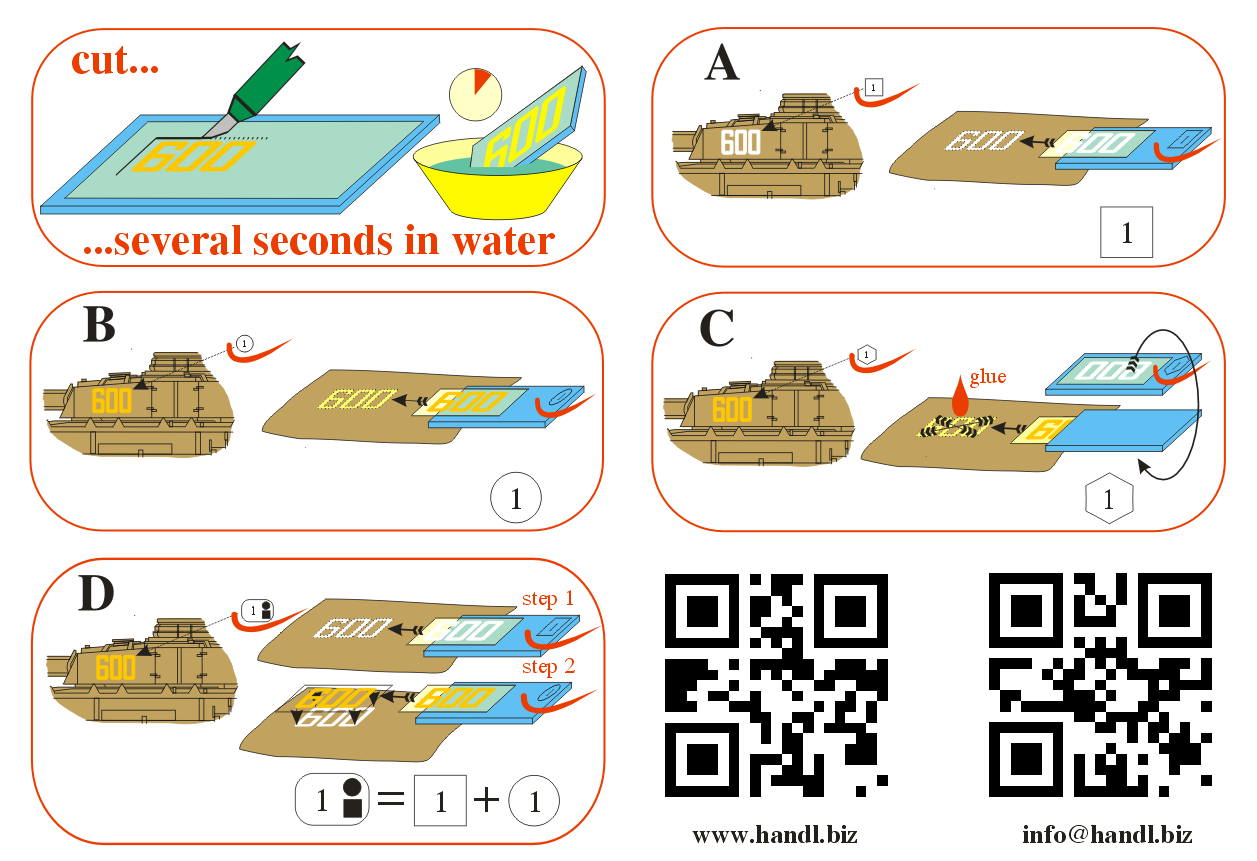

Decal needs to be cut out first, and applied on the kit after. There are three ways of applying the decal.

Schematic A and B – One decal (white or coloured)

White or coloured decal, which is being applied on white surface can be applied normally.

Schematic C – Inverse decals

Printing technology does not allow us to print white colour under the whole decal, but it allows printing the white decal over it. White colour printed like this does not have the same density. It is less intensive on darker shades of colours. On the other hand, it is very intensive on lighter shades. In surfaces, where there is only white colour, the density is 100%. This way, the strong contrasts between colours can be suppressed.

Inverse decal is used in cases, where the decal is very small, or it would be difficult to precisely apply coloured decal on white background decal in such way, that it could not be seen. Inverse decal is mirrored, and it is also applied on the kit inversely. The layer of glue between the decal and the decal paper is working as a separator, not as a glue. The glue is put on the kit first (any water-based dispersion adhesive) and then the decal is applied inversely on it.

Schematic D – Two decals

In general, decals consist of paper medium, layer of glue, background varnish, backgroudn white colour, and custom visible graphic. White background colour is under the whole decal, and its job is to prevent the kit colour to be seen through it. Because the technology does not allow us to print white colour under the whole decal, it is made from two layers. First, the white background decal is applied. After it is consisted of background white colour and visible white colour. After it dries, the coloured decal without any white colour should be applied. You do not have to separate the decals with a layer of varnish.

Varnish

It is not needed to relaquer the decals before the application, as they will not fall apart when applied. Because the decals are very thin, they may be difficult to apply on the surface, when they are of large size (Truck decals). In this case, it may be better to relaquer before application (even with several layers). The reason is not the potential damage, but increase of the thickness and making the application easier.

Use only synthetic or acrylic varnishes. Do not use any varnishes based on organic solvents (eg. acetonic).

Liquid decal adapters

It is possible to use liquid decal adapters. Every manufacturer uses different composition, which means that, that it is better to try them first. For example on the Handl model accessories logo, which is part of every decal. Because the decals are very thin, we do not recommend using strong and aggressive decal adapters.